Anamnesia

The Excellence of Custom Jewelry

BRACELETS

rings

loops

necklaces

sets

other

Our Manufacturing Process

The drawing

Previously created on paper with pencil or gouache, it now takes the form of a 3D computer graphic, allowing for a perfect representation of the volumes. This is the genesis of your project, the first concrete visualization of your future jewelry. It is from this computer graphic that we can establish a final budget and make any necessary technical adjustments.

The model

Thanks to 3D printers, this stage of your jewelry creation is crucial. What was once just a drawing becomes a first physical draft, a wax cast with a shaping and a representation of the volumes consistent with the final piece. While creating a model isn't mandatory, it allows you to better understand your future piece. This is the last moment to make any modifications.

The choice of stone

It will be tailored to your preferences and budget. All the stones offered for our creations are certified by gemological experts validated by the FGA (Fellow of the Gemological Association). We also use independent laboratories such as HRD/GIA for diamonds. While natural colored stones are obviously preferred, it is always possible to choose stones that have been lightly heated but not treated.

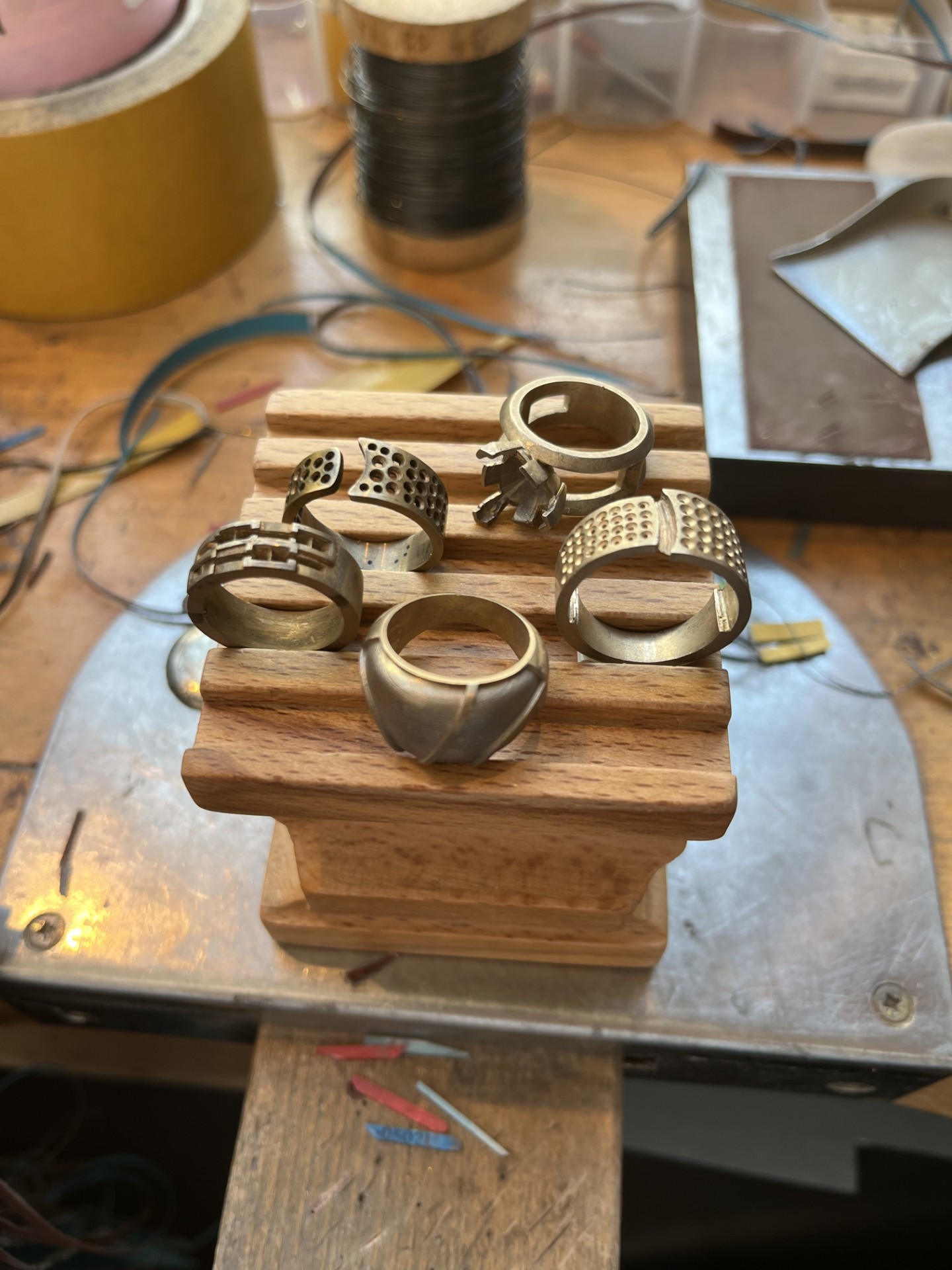

Cast iron

A magical step that transforms wax into gold. A mold is made around the wax, creating an imprint of the final piece of jewelry, and the whole thing is placed in an induction furnace. Under the effect of the heat, the wax disappears and the metal heats up until it melts. The next step is the casting machine. The gold is sent under pressure to replace the wax. Once cooled, the whole thing becomes a raw cast iron that now needs to be refined.

The cast iron catch-up.

This involves a methodical cleaning of the cast iron, allowing imperfections to be corrected and the angles of the piece to be refined. The openwork is obviously not overlooked, and this work on the material is an additional step toward the final result. All the forging elements are added to the piece, allowing for its assembly.

Crimping.

Or the stone setting. This is performed by a qualified jewelry and fine jewelry setter whose job is to place the stones on our cast iron. They will shape the prongs, refine them, and adjust the grain.

Polishing and rhodium plating

The final step in our creation involves a surface treatment of the piece to give it its full shine. Intermediate steps such as pre-polishing and punching are performed in between.

to be inspired

Anamnesia

Do you like what you see?